Choosing the Right Controlled-Environment GloveBox for Lithium-Ion Battery Applications

Understanding the Importance of Controlled Environment GloveBoxes

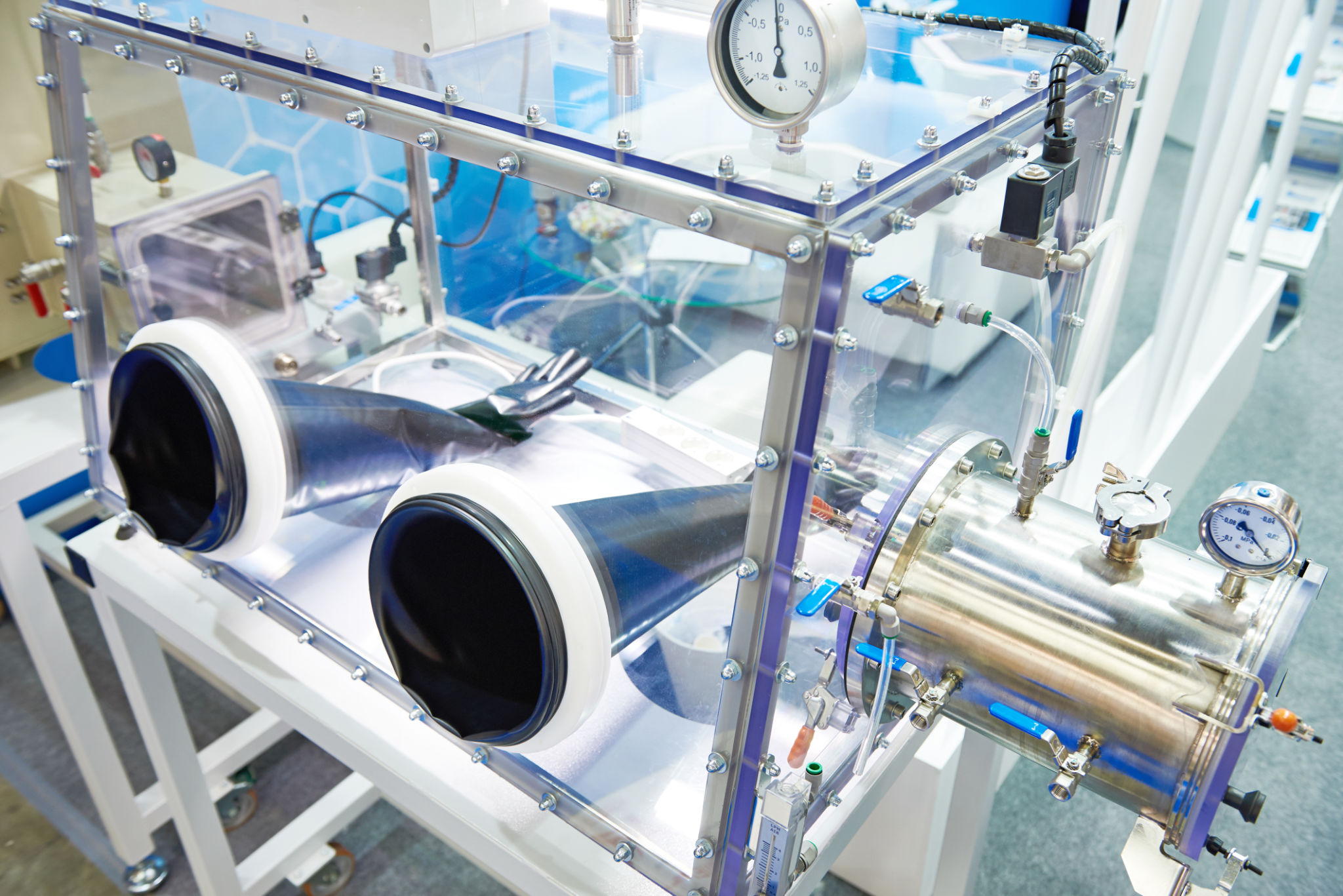

In the realm of ion-lithium battery applications, maintaining a controlled environment is crucial. Ion-lithium batteries are sensitive to contaminants such as moisture and oxygen, which can significantly affect their performance and longevity. Therefore, selecting the appropriate glovebox is a decisive factor that can influence the efficiency and safety of battery production processes.

A controlled environment glovebox is designed to provide a sealed space where specific atmospheric conditions can be maintained. This ensures that sensitive materials, like those used in ion-lithium batteries, are handled in an optimal environment, free from any external contaminants. Whether you're in research or production, the right glovebox can make all the difference.

1. Application Requirements

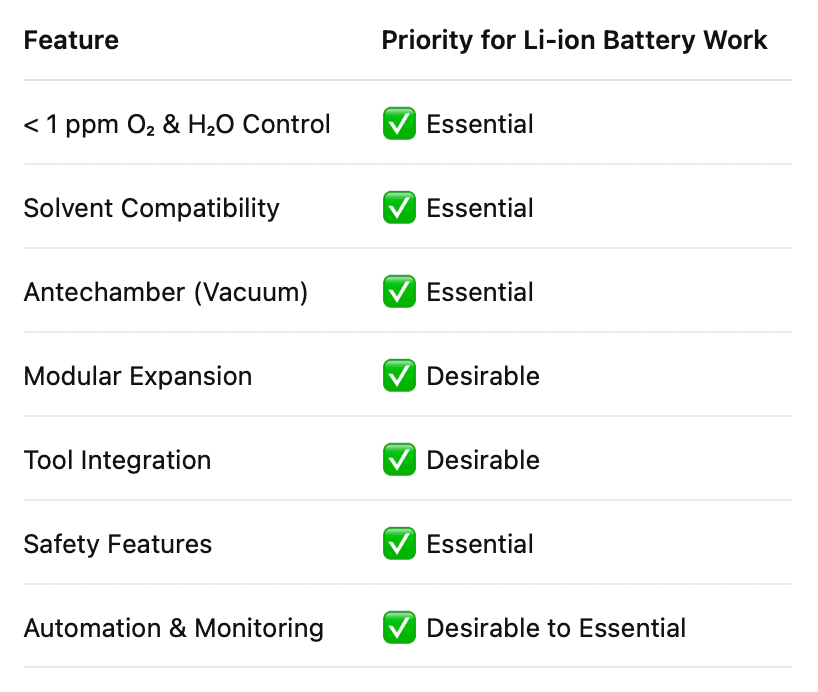

When choosing a glovebox for ion-lithium battery applications, it is important to consider several key features. The first is atmosphere control. The glovebox should allow precise control over humidity and oxygen levels, typically maintaining these below 1 ppm to ensure maximum protection for sensitive materials.

Define what you’ll be doing inside the glovebox:

- Battery assembly (coin cell, pouch cell, cylindrical)

- Electrolyte handling (volatile, flammable, toxic?)

- Material testing or R&D (dry powders, cathode/anode prep)

- Lithium Evaporation and/or PVD Coating

- Cycling or aging tests within the box

Each of these may influence the glovebox configuration, safety features, and size.

2. Inert Atmosphere Control

A lithium-ion battery glovebox should operate with ultra-low H₂O and O₂ levels:

- Look for <1 ppm O₂ and H₂O capability.

- Choose a box with automated purging and monitoring systems.

- Use high-purity Argon or Nitrogen as the inert gas.

Recommendation: A glovebox with a closed-loop circulation system with integrated purification columns (for O₂ and H₂O) is ideal.

3. Material Compatibility

Ensure the internal surfaces and materials are resistant to solvents and corrosive electrolytes (e.g., lithium hexafluorophosphate in EC/DMC).

Recommendation: Stainless steel 304/316 interiors and Solvent Trap (Large Capacity one or Regenerable one) are recommended.

4. Modularity and Customization Options

The ability to customize and expand a glovebox system is invaluable in a dynamic research or manufacturing setting. Modularity allows you to add or modify components as your needs evolve. Look for systems that offer interchangeable parts or accessories, such as shelves or gas purification units, which can be tailored to specific battery production requirements.

Furthermore, consider the glovebox's size and configuration. It should fit within your lab or production space while accommodating all necessary equipment and materials. Larger gloveboxes may offer more flexibility but require more space and potentially higher operating costs.

Recommendation: Modular gloveboxes allow future expansion (e.g., adding antechambers, ovens, feedthoughts, Rapid Thermal Process Systems, Thin Coating Units (PVD/CVD)).

5. Antechamber System

Needed for transferring materials in/out without contaminating the main chamber.

Look for fast-purge, vacuum-compatible antechambers, ideally with both small and large chamber options.

Recommendation: In most cases, the standard GloveBox system will be equipped with both a small and a large antechamber. If you are not planning to use the large antechamber too often, go with the manual one!

6. Safety Systems

Lithium samples can be flammable or reactive. The glovebox should include:

- Over-pressure relief valves

- Explosion-proofing or fire suppression (especially if volatile solvents are handled)

- Grounding features for electrostatic discharge protection

7. Integrated Tools & Feedthroughs

Battery R&D often requires:

- Crimping tools

- Vacuum pumps

- Electrical and vacuum/gas feedthroughs

- Heated stages or glovebox-integrated ovens

Recommendation: Choose a glovebox that supports customizable ports and tool integration.

8. Monitoring and Automation

- Continuous monitoring of O₂, H₂O, and pressure

- Automatic Purge Valve

- Automatic regeneration of purification columns

- Alarm systems for deviations in environment

Recommendation: In most cases, when the application requires the use of a solvent, go with the Automated Purge Valve option. It is one of the most efficient ways to purge the GloveBox module without saturating the purifier and while extending the solvent trap’s lifespan.

Conclusion

Selecting the right controlled environment glovebox for ion-lithium battery applications requires careful consideration of various factors. By focusing on atmosphere control, construction quality, modularity, automation, safety features, and cost-effectiveness, you can make an informed decision that enhances both the performance and safety of your operations.

With the right glovebox in place, you ensure that your lithium sample processes are conducted in an optimal environment, ultimately leading to better product outcomes and increased operational efficiency.